Innovations in Automation: The KR 3 AGILUS 6 Axis Industrial Robot for Efficient Material and Food Handling

Introduction to KR 3 AGILUS

In the rapidly evolving world of industrial automation, innovations continue to reshape how businesses approach efficiency and productivity. One such groundbreaking innovation is the KR 3 AGILUS 6 axis industrial robot, designed specifically for efficient material and food handling. This state-of-the-art robot is transforming industries by offering unparalleled precision and speed.

Features of the KR 3 AGILUS

The KR 3 AGILUS stands out with its compact design and versatility, making it suitable for various applications. It boasts six axes, enabling a full range of motion that mimics human arm movements. This flexibility is crucial for tasks requiring intricate handling and precise placement.

Key features of the KR 3 AGILUS include:

- High speed: Capable of executing tasks at remarkable speeds, thereby reducing cycle times and increasing throughput.

- Precision: Offers exceptional accuracy, ensuring minimal waste and maximum quality control.

- Small footprint: Its compact size allows for seamless integration into existing production lines without requiring significant changes.

Applications in Material Handling

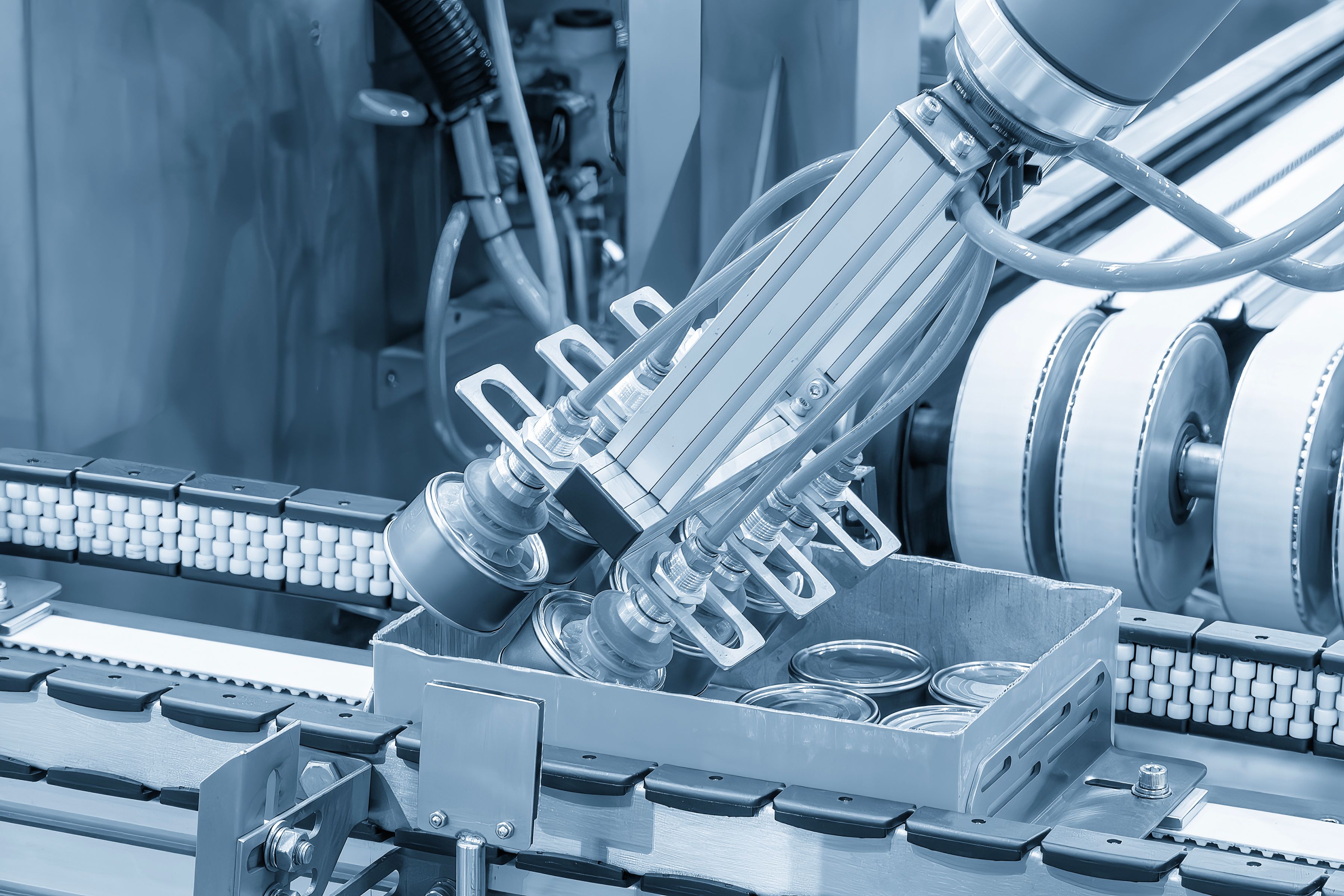

The KR 3 AGILUS excels in material handling applications, providing businesses with the ability to automate repetitive and labor-intensive tasks. Its dexterity and speed are particularly beneficial for sorting, packaging, and palletizing operations.

This robot can handle a wide range of materials, from delicate items to heavier components, ensuring that each item is moved with care and precision. By automating these processes, companies can achieve higher productivity levels while reducing manual labor costs.

Transforming the Food Industry

In the food industry, the KR 3 AGILUS has become a game-changer. Its ability to handle food products hygienically and efficiently is invaluable in maintaining high safety standards. From picking and placing to packaging, this robot ensures that food items are processed quickly and safely.

Moreover, the robot's precision helps in reducing waste by minimizing errors during handling, which is critical in a sector where margins are often tight. The automation provided by the KR 3 AGILUS allows food manufacturers to scale their operations without sacrificing quality.

Advantages Over Traditional Methods

Compared to traditional manual methods, the KR 3 AGILUS offers numerous advantages. Its reliability means that operations can run continuously without breaks, leading to increased uptime and productivity. Additionally, it reduces the risk of workplace injuries associated with repetitive tasks.

The robot's ability to perform complex tasks with ease also allows businesses to reallocate human resources to more strategic roles, enhancing overall operational efficiency.

Integration and Adaptability

Integrating the KR 3 AGILUS into existing systems is straightforward thanks to its user-friendly interface and compatibility with various control systems. This adaptability ensures that businesses can quickly adopt this technology without extensive training or infrastructure changes.

Its versatility across different industries means that it can be used in diverse applications, from small workshops to large manufacturing plants, making it a valuable asset for any operation seeking to enhance automation capabilities.

The Future of Robotics in Industry

As industries continue to evolve, the role of robotics like the KR 3 AGILUS will become even more prominent. With advancements in artificial intelligence and machine learning, these robots will become smarter and more autonomous, further boosting efficiency and productivity.

The KR 3 AGILUS represents a significant step forward in automation technology, setting a benchmark for future innovations in industrial robotics. Its impact on material and food handling is just the beginning of what is possible as we move towards a more automated world.

Conclusion

The KR 3 AGILUS 6 axis industrial robot is at the forefront of automation innovation, offering remarkable benefits for material and food handling processes. By integrating this advanced technology into their operations, businesses can achieve new levels of efficiency, quality, and productivity, paving the way for a more automated future.